LINES AND PLANTS FOR DRY PASTA

La Parmigiana has always paid particular attention to small and medium-sized artisan pasta factories that produce high quality dry pasta with diversification of products and ingredients and use static dryers for the drying process.

Keeping this in mind, La Parmigiana has developed and optimized fully automated lines with a capacity of 150 kg/h to 600 kg/h of dry product. These lines have been designed to satisfy different markets and therefore different needs. Our presses are equipped with systems that allow You to work and obtain a product of the highest quality.

Plants for the production of dry pasta can be customized according to each customer’s needs.

Our machinery for dry pasta lines are totally designed within the company by a team of designers with decades of experience in the pasta making industry. This guarantees reliable and long-lasting machines.

— Production of different pasta sizes

Our pasta production lines can be designed for the production of multiple shapes. The same line can produce short, long, special pasta and a wide range of shapes derived from one pasta sheet:

- Nests

- Pasta sticks and krajanca

- Long pasta spread on trays

- Lasagna

- Pasta skein and folded pasta

The automation level can vary according to a customer’s requests and the total line can be controlled and managed by just one operator.

The after-sales service is guaranteed by specialized technicians.

— Lines and Plants for Dry Pasta

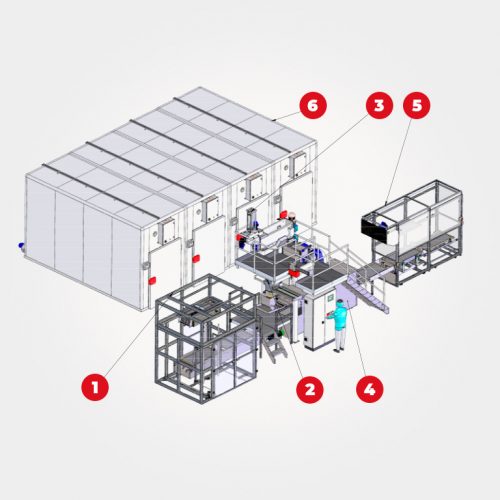

— Short Pasta Line

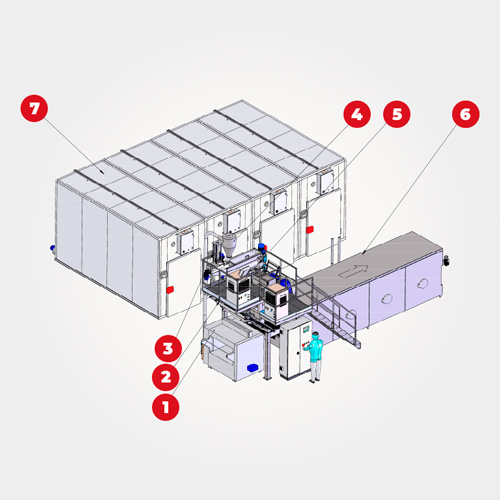

— Long Pasta Line

1 = SPREDING MACHINE 1200

2 = LINEAR HEAD 1200/span>

3 = PRE-MIXER VOLUMIX

4 = SCRAPS SHREDDER GROUP

5 = PRESS FOR PASTA PRODUCTION

6 = PRE-DRYER

7 = DRYERS

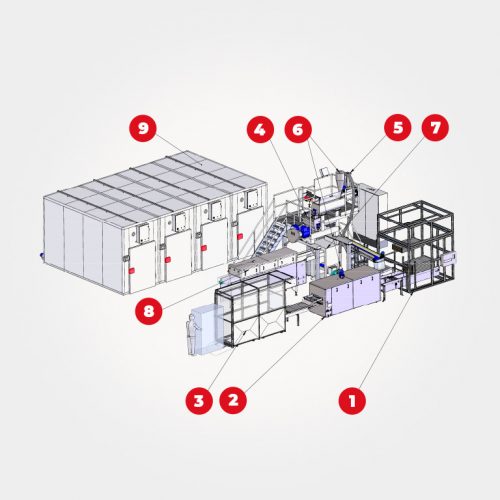

— Long/Short Pasta Line

1 = TRAYS UNLOADER WITH TRAYS FEEDER STORAGE

2 = PRE-DRYER

3 = TRAYS STACKER

4 = PRESS FOR LONG/SHORT PASTA

5 = PRE-MIXER VOLUMIX

6 = SCRAPS SHREDDER GROUP

7 = SPREADING MACHINE

8 = TUNNEL 600

9 = DRYERS

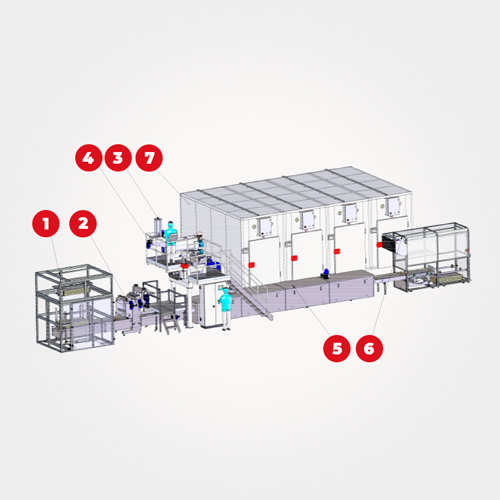

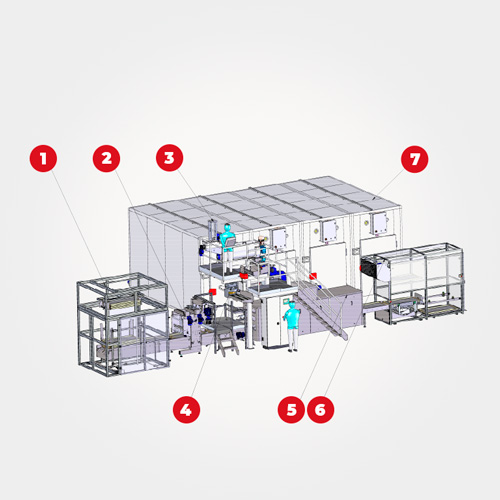

— Nests and Lasagna Line

1 = TRAYS UNLOADER WITH TRAYS FEEDER STORAGE

2 = NESTING MACHINE + LASAGNA GROUP

3 = PRE-MIXER VOLUMIX

4 = PRESS WITH LINEAR HEAD 600

5 = PRE-DRYER TUNNEL 8M

6 = TRAYS STACKER

7 = DRYERS